Edible oils are a staple in kitchens and industries worldwide, playing a crucial role in our daily lives. From the food we eat to the cosmetics we use, the quality of these oils significantly impacts our health and well-being. This is where the edible oil refining machine comes into play, ensuring that the oils we consume meet the highest standards of purity and safety.

Understanding the Need for Refinement

Raw vegetable oils obtained through pressing or solvent extraction contain various impurities, including free fatty acids, phospholipids, and other components that can cause undesirable flavors, odors, and appearances. To transform these raw oils into the clear, odorless, and stable products we use, a refining process is essential.

The Refining Process: A Step-by-Step Guide

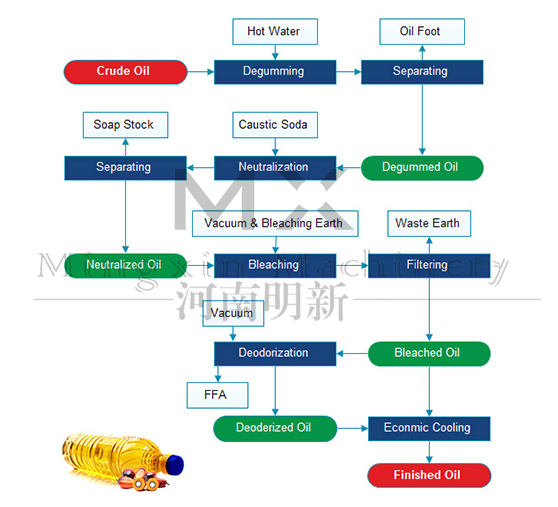

Degumming: This initial step involves removing phospholipids or gums from the oil. In the physical refining route, special degumming is applied, while in the chemical refining route, water degumming is the norm.

Neutralization: Free fatty acids are neutralized in this stage, creating aqueous soap that is then removed from the oil using centrifuges. This step is part of the chemical refining route.

Dewaxing: Certain oils, like sunflower and corn, undergo dewaxing to achieve cold stability, which ensures the oil retains clarity at low temperatures.

Bleaching: The oil is then treated with bleaching agents to remove color and any residual impurities, enhancing its appearance and stability.

Deodorizing: The final step involves stripping off any volatile components that contribute to the oil’s odor, resulting in a neutral-smelling final product.

Innovations and Sustainability in Oil Refining

The edible oil industry has come a long way, with technological advancements leading to more efficient and sustainable refining processes.

The edible oil refining machine is a marvel of modern engineering, turning raw, crude oils into the refined products that are an integral part of our lives. With a focus on quality, safety, and sustainability, the industry is well-equipped to meet the growing global demand for edible oils.